Sino-Japanese Precision Development, Constant Stable Mixing

Redefine the new height of cementing material mixing with military-grade quality and intelligent technology!

Incorporating Japanese precision machinery manufacturing processes and Chinese intelligent control technology, the Sino-Japanese R&D team has deeply developed over 8 years. Key components such as bearings and transmission devices adopt Japanese imported materials, paired with China's self-developed intelligent control system, ensuring mixing stability and durability reach international leading levels, with a 90% reduction in failure rate and a 150% extension in service life.

- Worry-Free Operation, Stable Start Intelligent Control – Equipped with a U.S.-imported driver, precisely controls rotation speed, intelligently locks speed within 4000rpm for low-speed start, prevents splashing from misoperation, and ensures safer operation.

- Wide speed adjustment range: 1000–18000 RPM stepless speed regulation, meeting different mixing needs in petroleum cementing, geological exploration, building materials, and other fields. Supports custom speed settings for personalized mixing requirements of special samples.

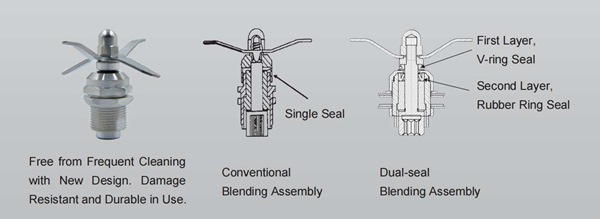

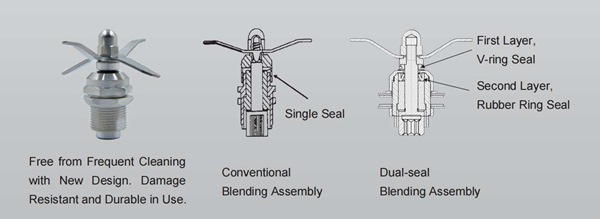

Adopts a dual-seal protection structure:

- Inner fluororubber soft seal: High-elasticity material closely fits the mixing shaft, with excellent dynamic sealing performance, effectively preventing leakage of cement slurry, chemical reagents, etc., and stable operation even in high-temperature and strong-corrosion environments.

- Outer stainless steel hard seal: Precision-machined and surface-hardened, resistant to 150°C high temperature and high-wear conditions, with a sealing pressure of up to 1.8MPa and a service life 3 times that of ordinary seals, ensuring long-term stable operation with zero leakage.

- Jog cleaning function: After the experiment, simply add a small amount of water to effectively clean the mixing assembly and the bottom of the slurry cup through the jog cleaning function.

- Rapid defoaming treatment: After mixing, the automatic defoaming mode starts. Through a unique mixing trajectory and speed control, it effectively eliminates bubbles in the cement slurry, making the sample directly meet API standard testing requirements without additional defoaming treatment, effectively improving experimental efficiency.

- Mixing cup: Standard-equipped with a U.S.-original 1L stainless steel mixing cup, compliant with ASTM standards, with a smooth and corrosion-resistant inner wall (roughness Ra≤0.8μm), ensuring no contamination during sample mixing and easy cleaning.

Suitable for multiple industries including oil and gas cementing engineering, geological exploration, building material R&D, coating chemicals, food and pharmaceuticals:

- Cementing engineering: Precisely mixes cement slurry and cementing additives to ensure uniform material mixing, optimize cementing formulations, and improve cementing quality and construction efficiency.

- Material R&D: Provides a stable and reliable mixing environment for the development of new building materials and special coatings, helping breakthroughs and innovations in product performance.

- Quality control: Strictly controls the mixing quality of raw materials and finished products to ensure all product indicators meet standards.

- A Sinopec drilling project: After using the Constant speed mixer, the uniformity of cement slurry mixing increased by 40%, and the cementing construction success rate rose from 82% to 93%, effectively reducing construction costs and risks.

- A Japanese building material laboratory: With the instrument's automatic cleaning and defoaming functions, experimental efficiency increased by 70%, annual labor costs were saved by approximately ¥150,000, and multiple high-performance building materials were successfully developed.

- Authoritative certifications: Passed ISO 9001 quality management system certification, EU CE certification, API-related certifications, etc., strictly following international standards for production, with quality you can trust.

- Service support: Sino-Japanese expert joint team provides 7×24-hour online consultation, remote debugging, and fault diagnosis services; over 30 service outlets nationwide, core components under 3-year warranty, and 24-hour on-site maintenance response.

- Training services: Free professional operation training provided, including Sino-Japanese bilingual operation manuals and video tutorials to help you quickly master instrument use and maintenance skills.

Experience Efficient Mixing Now

Click the button below, fill out the requirement form, and get:

- Customized model selection solutions

- Free sample mixing test opportunities

- One-on-one technical consultation with Sino-Japanese experts

- Limited-time discount offers

Immediate Consultation

Q: How is the mixer's rotational speed stability ensured?

A: NHJQ uses a U.S.-imported driver with an advanced intelligent control system to achieve high-precision stable speed control within ±0.1% RPM, ensuring uniform mixing without interference from external factors.

Q: Does the dual-seal structure require frequent maintenance?

A: No frequent maintenance is needed under normal use. The outer hard seal is inspected and replaced every 2–3 years, and the inner soft seal is covered by a 1-year warranty with low maintenance costs and simple operation.

Q: Can the automatic cleaning function thoroughly remove stubborn stains?

A: The automatic cleaning program uses a combination of high-pressure spraying and rotational scrubbing with special cleaning agents to effectively remove various stubborn stains. Tests show a 99% cleaning rate for stains like cement slurry and high-viscosity coatings, meeting laboratory cleaning standards.