A new generation of fully automatic instrument used to simulate the high temperature and high pressure environment underground and continuously measure the consistency change and thickening time of oil well cement.

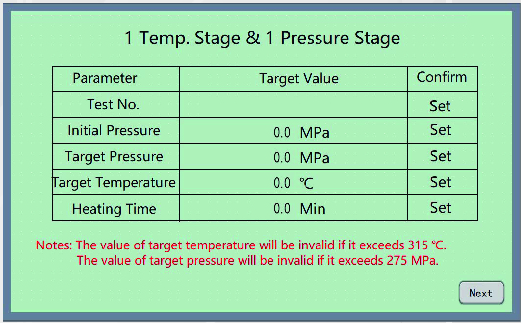

This instrument adopts a touch screen design, and experimental parameters can be set on it without frequent operations. The experimental data and experimental curves can be observed through the touch screen, and the data can be saved and output through screenshots. The experimental data can be seen at a glance and be set, observed and saved through computer software.

Technical Description of the Nithons Pressurized Consistometer

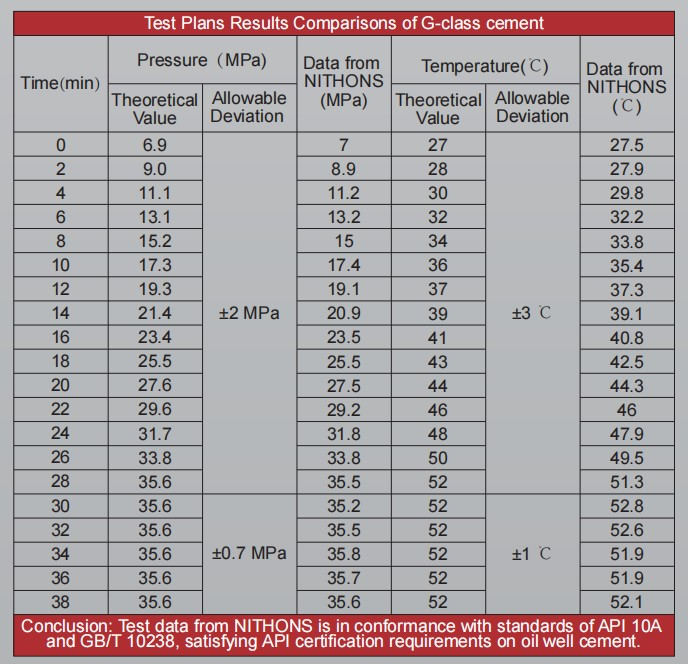

The Nithons Pressurized Consistometer is a cutting-edge testing instrument designed for oil well cementing engineering, specifically engineered to simulate downhole high-temperature and high-pressure (HTHP) conditions. By accurately replicating extreme wellbore environments, this device enables precise evaluation of cement slurry thickening performance, ensuring optimal cementing quality and preventing operational failures caused by inadequate slurry behavior.

Extreme Testing Capability

Dual-Mode Design

Precision Control System

Exceptional Stability & Durability

Intelligent Operation & Data Management

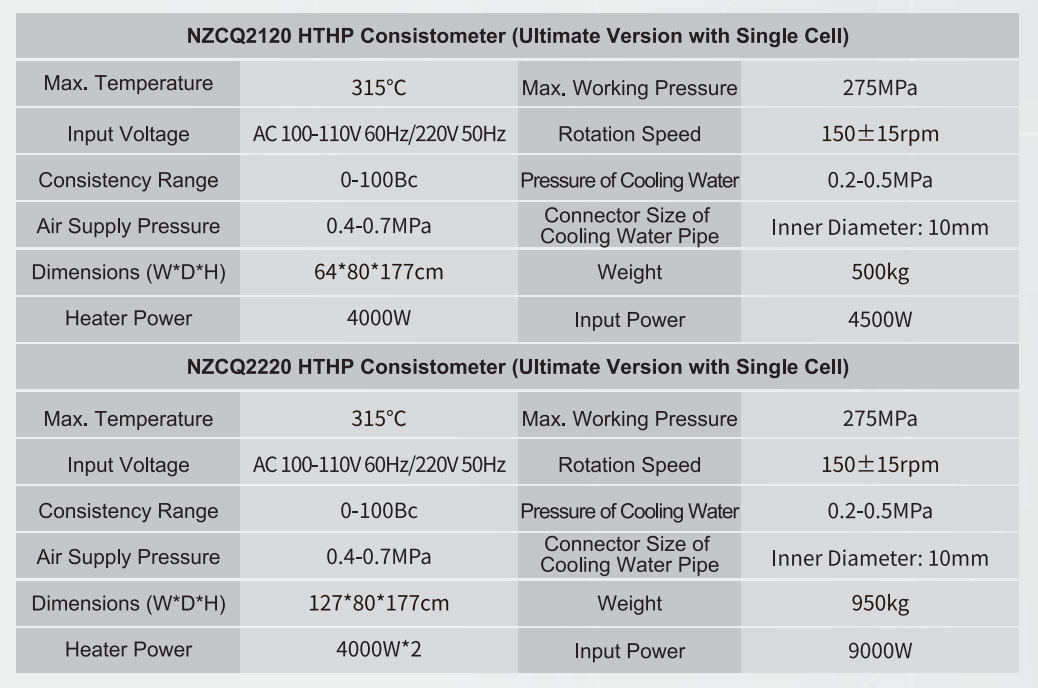

Technical Specifications

The Nithons Pressurized Consistometer provides critical data for:

With its robust construction, precision engineering, and advanced automation, the Nithons Pressurized Consistometer is an indispensable tool for cementing laboratories and field operations, ensuring reliable well integrity in the most challenging environments.